Threaded rod

A threaded rod, also known as a stud, is a relatively long rod that is threaded on both ends; the thread may extend along the complete length of the rod.[1] They are designed to be used in tension.[2] Threaded rod in bar stock form is often called all-thread.

Contents |

Studs

Studs may have a drive slot in one end to facilitate installing the stud.

Types

For studs that are not completely threaded, there are two types of studs: full-bodied studs, and undercut studs. Full-bodied studs have a shank equal to the major diameter of the thread. Undercut studs have a shank equal to the pitch diameter of the screw thread. Undercut studs are designed to better distribute axial stresses. In a full-bodied stud the stresses are greater in the threads than in the shank.[3]

Undercut studs (rolled thread) are also stronger because the metal is "rolled" up to the major diameter, not removed. This preserves the grain of the steel, and in some cases even enhances it. Full bodied studs (cut thread) are weaker because metal is removed to create the thread, disturbing the grain of the steel.[4][5]

Undercut studs are only required in applications where the stud is exposed to fatigue. Cut threads are entirely suitable for many applications, even when rolled threads might be slightly stronger. Mass-produced fasteners (standard bolts and studs) are usually rolled, but jobbed parts with custom features and small lot sizes are likely to be cut.

Strength

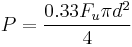

The allowable tensile force for a non-undercut threaded rod is defined by the American Institute of Steel Construction (AISC) as:[6]

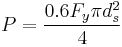

where d is the nominal diameter and Fu is the ultimate tensile strength of the material. For undercut threaded rods the allowable tensile stress is defined as:[6]

where ds is the diameter of the shank and Fy is the yield strength of the material.

Class

Metric threaded rods are marked on the end with a color code to define the class. The color codes are:[7]

- Unmarked — 4.6 class

- Yellow — 8.8 class

- Green — A2 stainless steel (304)

- Red — A4 stainless steel (316)

- White — 10.9 class

References

- ^ Soled, Julius (1957), Fasteners handbook, Reinhold Publishing, p. 90, http://books.google.com/books?id=8OdSAAAAMAAJ&pg=PA347.

- ^ Speck, James A. (1997), Mechanical fastening, joining, and assembly, CRC Press, p. 54, ISBN 9780824798352, http://books.google.com/books?id=6KhAbKYFbH4C&pg=PA54.

- ^ Mavrigian, Mike (2008), High Performance Fasteners & Plumbing, Penguin Group, p. 49, ISBN 9781557885234, http://books.google.com/books?id=3weCjR8nrJ0C&pg=PT56.

- ^ Green 1996, pp. 1828–1830.

- ^ Green 1996, p. 1842

- ^ a b Williams, Alan (2001), Structural Steel Design, 1, Kaplan AEC Engineering, p. 151, ISBN 9781580010559, http://books.google.com/books?id=vQ2ZqdhR3hUC&pg=PA151.

- ^ http://www.bomet.com/en/quality

Bibliography

- Green, Robert E. et al. (eds) (1996), Machinery's Handbook (25 ed.), New York, NY, USA: Industrial Press, ISBN 978-0-8311-2575-2, http://www.worldcat.org/title/machinerys-handbook/oclc/473691581.